Segmented Filtration

Easily Adapted to Varying Requirements

Easily Adapted to Varying Requirements

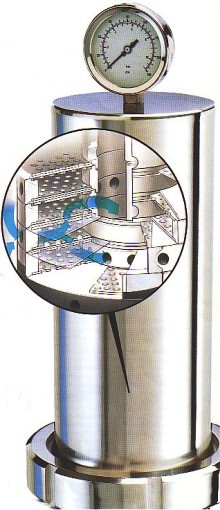

MicroPure Segmented Filters sandwich self-sealing filter media between specially designed segments of stainless steel, clamped securely by a stainless steel tension rod connecting the end segments to form the cartridge.

In a typical application (see circular illustration at right), air/gas or liquid flows into openings in the outside of a segment and passes through the filter medium into an adjacent segment. The filtered air/gas or liquid then exits through openings at the center of the cartridge and out of the filter housing.

The number of segments and the type of filter medium used in each MicroPure Segmented Filter are determined by your application. MicroPure offers filter media in polytetrafluoroethylene (PTFE) membranes for sterile filtration and woven stainless steel for other applications.

Since each filter medium functions independently, you can increase throughput significantly by adding segments and filter media. The cartridge can be disassembled and reassembled quickly and easily.

Unlike conventional filter cartridges, the two-way MicroPure design provides equal support for the filter media in both directions so you can reverse the flow if your application requires.

SegmaPure Sterile Air/Gas Filter

Why you need sterile air or gas

To reduce batch contamination, spoilage and product loss, effective sterile air or gas filtration is a necessary part of your process. Especially important in the food, beverage, and pharmaceutical industries, sterile air/gas filtration protects your product from harmful submicron particle contamination and bacterial transfer or growth.

It also helps protect production yield, especially in high-tech industries (electronics, plating, magnetic media, etc.) where submicron particle contamination can significantly reduce yields, resulting in product and dollar loss. The use of high efficiency submicron air and gas filters have become a standard "current good manufacturing practice" allowing for more productive and economical processing.

No other filter offers this combination of features:

- Allows for bi-directional flow

- In situ steam sterilization (up to 150 times)

- Clean-in-place with steam or common sanitizing agent

Durable Materials of Construction- Stainless Steel and PTFE

- Broad range of chemical compatibility

- Autoclavable, high temperature tolerance

- Low extractable levels

Unique Flat, Double Layer Membrane Design

- Low replacement cost compared to conventional cartridges

- Simple, on-site visual inspection or "plating" of indvidual filter membrane; easily removable for laboratory analysis or culture

Perforated Stainless Steel Modular Segments

SegmaFlo Steam Filter

Why you need filtered steam

To protect costly equipment, maintain processing efficiency and reduce downtime, it's important to remove scale and debris that are common in most systems. Filtered steam will protect valves, process equipment, and process filters from damage.

To protect product purity, you need culinary grade steam with particles no larger than 2 microns. When filtered through a SegamFlo Steam Filter, steam used to agitate, mix, or cook food will be free from contaminates which can spoil the appearance, smell, or taste of your product.

No other filter offers this combination of features:

- Segmented design allows exchange of media to meet changing requirements, to inspect elements, or to replace old elements

- Available in media pore grades from 2 to 200 microns-- and 4 diameter sizes-- for exceptional versatility

- Meets FDA/PMO criteria and 3A dairy standards for culinary steam

- Housing and segments warranted for 5 yrs

- Bi-directional flow capability

- Built of a single material-high-grade stainless steel -- to tolerate extreme pressure and temperature variations for unlimited reusability

- Easy to design into virtually any process system

SegmaFlo Trap Filter

Why you need filtered liquids

To protect product quality, maintain efficiency and reduce downtime, it's important to remove particulates from component liquids and final liquid products prior to filling. SegmaFlo Trap Filters from MicroPure help prevent line debris from entering your product by filtering out particulate and other process contaminants as small as 2 microns.

No other filter offers this combination of features:

- Modular, segemented design reduces downtime, adds versatility

- Permits simple exchange of media to meet changing requirements

- Allows easy inspection of media

- Simplifies process of replacing old media

- Available in media pore grades from 2 to 200 microns--and 4 diameter sizes--for application versatility

- Housing and segments warranted for 5 yrs

- Bi-directional flow capability

- Built of a single material--high-grade stainless steel--to tolerate extreme pressure and temperature variations for umlimited reusability

- Easily applied in virtually any process system

SegmaPure Sterile Tank Vent Filter

Why you need sterile tank vent filters

To reduce batch contamination, spoilage, and product loss, submicron filtration is a necessary part of your process--particularly if you are involved in industries that require sterile products (aseptic food, beverage, pharmaceutical, and others).

To maintain safe, balanced pressure during the filling or emptying of a storage vessel, tank vent or breather filters are essential to help reduce the possibility of contaminating your product.

No other filter offers this combination of features:

Perforated Stainless Steel Modular Segments

- Allows for supported bi-directional flow during sterile breathing on tanks and containers

- "In-situ" steam sterilization (up to 150 times)

- Clean-in-place with steam, or common sanitizing agent

Durable Materials of Construction--Stainless Steel and PTFE

- Broad range of chemical compatibility

- Autoclavable

- High temperature tolerance

Unique Flat, Double Layer Membrane Design

- Low replacement cost compared to conventional vent cartridges

- Double layer PTFE (redundant filtration) for additional safety and security

- Simple, on-site visual inspection or "plating" of individual filter membranes

- Long operational periods due to high throughput, low initial pressure drop, high capacity

Simplicity Of Design

- Easily mounted on tanks or containers

- Excellent breathing properties with weatherproof cover

- Simply add modular segments to increase capacity