Segmented Filtration

Easily Adapted to Varying Requirements

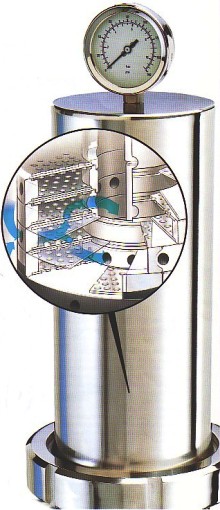

MicroPure Segmented Filters sandwich self-sealing filter media between specially designed segments of stainless steel, clamped securely by a stainless steel tension rod connecting the end segments to form the cartridge.

In a typical application (see circular illustration at right), air/gas or liquid flows into openings in the outside of a segment and passes through the filter medium into an adjacent segment. The filtered air/gas or liquid then exits through openings at the center of the cartridge and out of the filter housing.

The number of segments and the type of filter medium used in each MicroPure Segmented Filter are determined by your application. MicroPure offers filter media in polytetrafluoroethylene (PTFE) membranes for sterile filtration and woven stainless steel for other applications.

Since each filter medium functions independently, you can increase throughput significantly by adding segments and filter media. The cartridge can be disassembled and reassembled quickly and easily.

Unlike conventional filter cartridges, the two-way MicroPure design provides equal support for the filter media in both directions so you can reverse the flow if your application requires.

6 layer unit (without housing cover)

4 layer unit (without housing cover)

2 layer unit (without housing cover)

Increasing the filtration capacity in a MicroPure Segmented Filter is as simple as adding pairs of discs and additional media pieces.