Micro-Series

Finite’s Air and Gas Microfiltration Products

Membrane Elements and Housing Assemblies For:

- Semiconductor/Microelectronics

- Medical/Pharmaceutical

- Food and Beverage

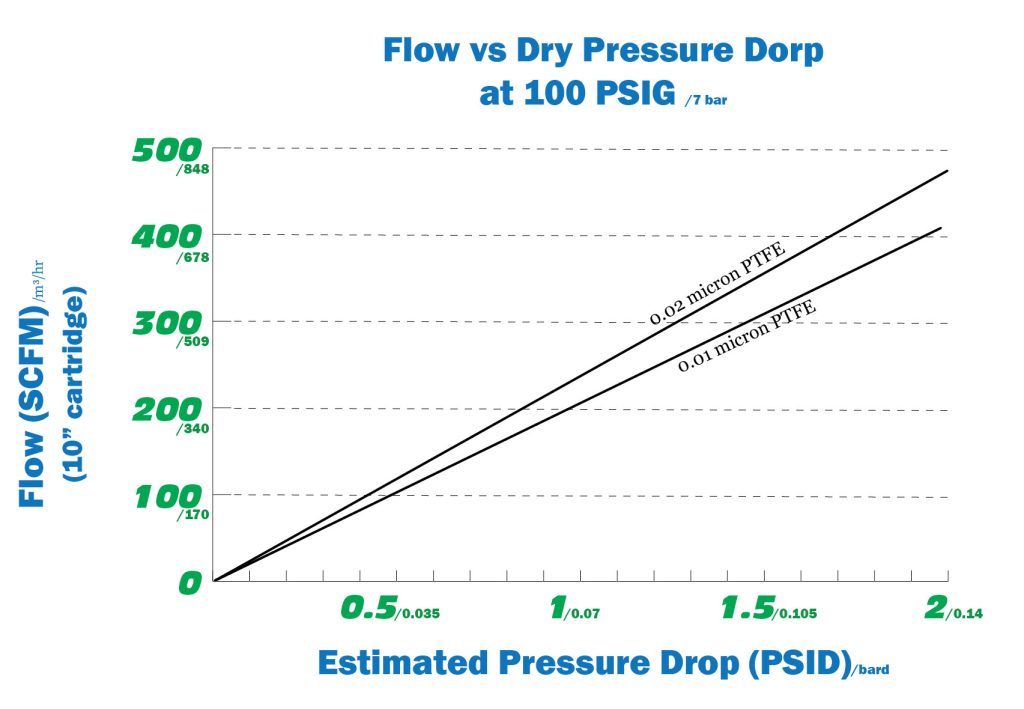

Finite® Filter’s Micro-Series filters are designed to provide absolute rated membrane filtration for the pharmaceutical, semiconductor, and for the food and beverage markets. Our pleated membrane media offers absolute removal ratings for contaminants as small as 0.01 μm while providing lower differential pressures than competitive membrane products.

Finite®s pleated PTFE media has the the highest efficiency and lowest pressure drop at rated flow in the filtration industry. These important factors provide substantial savings to you, our customers.

All of the filter housings are constructed of 316L stainless steel and have a max. pressure rating of 150 PSIG/10 bar. Connection sizes range from 1” NPT – 6” flange.

Industries & Applications

Semiconductor/Microelectronics

- Clean, dry air (CDA) final filters

- Hard disk manufacturing

- Automated disk testers

- Wafer drying systems

- CDA to replace use of nitrogen

- Wafer polishing equipment

Pharmaceutical/Medical

- Bag cleaning

- Laboratory air

- Filtration of bulk gases

- Bottle filling machines

- Venting of holding tanks

- Gas calibration equipment

Food and Beverage

- Aseptic packaging

- Blow molding

- Purging

- Air bearings/motors

- Conveying

- Tank padding

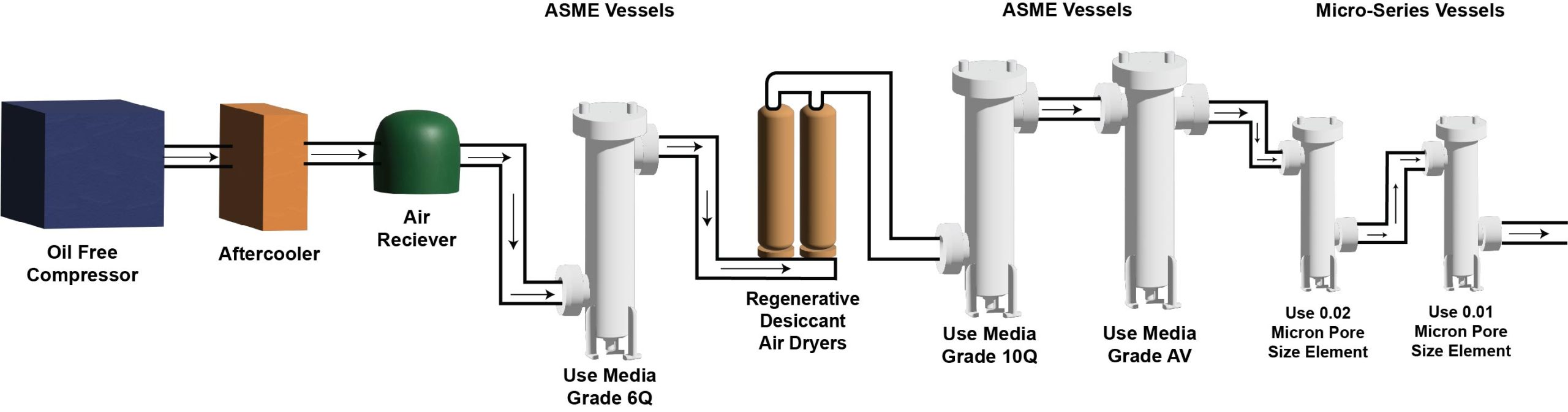

Typical Clean, Dry Air (CDA) Installations

Membrane Selection

Features and Benefits - PTFE Membrane

- PTFE membrane media is non-fiber releasing and provides for broad chemical compatibility

- The high flow rates and optimized surface area help reduce filter consumption

- Integrity tested - 100%

- Pleated construction provides broad high purity filtration area for maximum yields

- PTFE Memrane is biosafe in accordance with USP Class V1-121°C Plastics Tests

- Polypropylene support hardware, with fluorocarbon o-ring seals are able to withstands demanding operating conditions

- Narrow pore size distribution ensures the ultimate in retention and flow rates

- Parts are manufactured and packaged in Class 10 clean rooms

- 99.999999% (8 log) efficiency at specified removal ratings (0.01 μm, 0.02 μm)

Membrane Element Specifications

- Sealing Technology: Thermal Bonding

- O-Rings/Gaskets: Fluorocarbon

- Maximum Differential Pressure (FWD): 60 PSID

- Maximum Differential Pressure (REV): 50 PSID

- Packaging: Double bagged in Class 10 clean room

PTFE Membrane Elements

(PTFE Membrane Elements have polypropylene membrane support and polypropylene end caps)

How To Order Membrane Elements

Housing Selection

MT1 Series

- 316L Stainless Steel

- Thru-rod housing design

- 1” NPT threaded inlet and outlet ports

- Threaded vent and drain connections

- T-Type (line mounted design)

- Single double open end element design

- Cartridge lengths 10” and 20” available

- Fluorocarbon seals used throughout

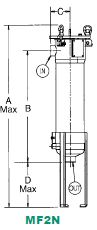

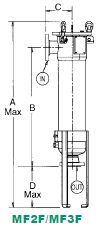

MF2 & MF3 Series

- 316L Stainless Steel

- Single fluorocarbon o-ring for positive housing seal

- Swing bolts w/ eyenuts

- ASME Code - UM Stamped

- Threaded vent and drain connections

- Adjustable leg height

- Flanged or threaded inlet and outlet connections

- Side inlet, bottom outlet

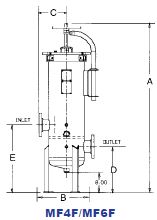

MF4 & MF6 Series

- 316L Stainless Steel

- Single fluorocarbon o-ringfor positive housing seal

- Swing bolts w/ eyenuts

- ASME Code - UM Stamped

- Threaded vent, drain, gauge connections

- Mechanical cover lift standard