Dual-Stage Compressed Air Filters - BA-Series

About Parker BA Series

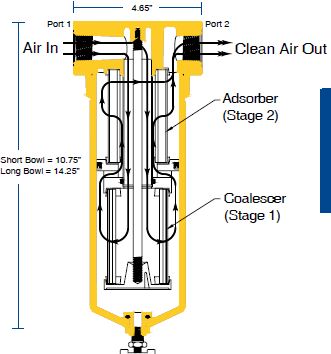

BA-Series filters are designed to be used as point-of-use breathing air filters. This combination unit contains both a fine grade coalescing filter element and an activated carbon vapor removal element.

BA-Series filters may also be used in applications requiring compressed air to be free of odor or taste-bearing hydrocarbons. Food/beverage applications are an Example of where compressed air comes in contact with the product. The BA-Series can also be used as a prefilter for critical needs such as zero air generators, membrane filters and many others!

Replacement elements are supplied in convenient repair kits which include one coalescing element, two activated carbon adsorber elements, and replacement seals. Two adsorber elements are supplied because the stage one coalescer will routinely outlive the extremely sensitive second stage adsorber element.

For severe applications with Excessive solid and liquid contaminants, the BA-Series should be preceded by Finite® H-Series (Bulletin 1300-993/USA) pre-coalescer or interceptor filters.

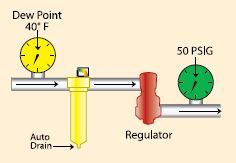

Finite® also supplies pressure regulators which can be used downstream of the BA-Series to lower system operating pressures to desired levels for breathing air applications. Please refer to Finite® bulletin Finite®s pleated PTFE media has the the highest efficiency and lowest pressure drop at rated flow in the filtration industry. These important factors provide substantial savings to you, our customers.

All of the filter housings are constructed of 316L stainless steel and have a max. pressure rating of 150 PSIG/10 bar. Connection sizes range from 1” NPT – 6” flange.

BA - Series Offers...

- Connection sizes: 1/4" - 1" NPT

- Flows: Up to 75 SCFM (128 m3/hr)

- Maximum Pressure: 500 PSIG (34 bar)

- Maximum Temperature: 175° F (79° C)

- Drain Port: 1/8" NPT with standard manual drain (float drain available)

Typical Applications

- Industrial Breathing Air

- Aircraft Cabin Air

- Zero Air Generator Prefilter

- Instrument Air

- Food Processing/Packaging

- Membrane Prefiltration

- Instrument Air Dryer Prefilter

Use any compressor with aftercooler and refrigerated dryer. Air intended for use as industrial breathing air and in decompression chambers.

CAUTION: Always use high temperature synthetic lubricants and monitor (alarm) for carbon monoxide concentrations exceeding established Maximum recommended levels. This system will not eliminate toxic gases!

OTHER SPECS MET: O.S.H.A. 29CFR 1910.134

How it works

Compressed air enters port: 1 of the housing and is directed down a hollow chamber into the firststage coalescing element (bottom). Oil, water and solid contaminant is removed with a 99.97% or higher efficiency as the air flows from the inside of the element to the outside. The coalesced liquid drains off the element into the bowl where it is removed either manually, or by an automatic float drain. The oil-free air then is redirected upwards to the inside of the adsorber element (top) by means of a non-bypassing separation device. The second stage’s activated carbon element collects hydrocarbon vapors as the air flows from the inside to the outside of the element. The purified air then exits through port 2 of the housing.

Note: This product does not remove toxic gases from the air stream. A carbon monoxide monitor is recommended.

Choice of Media Types

All BA filters have an activated carbon element (Stage 2). Depending on the application, you may either choose to use a micro-glass coalescer (C) or a micro-glass coalescer with a built-in prefilter (Q) (Stage 1.)

Stage 1

C:Micro-glass coalescer

Q:Micro-glass coalescer with built-in pleated prefilter

Grade 4

Grade 6

Stage 1 coalescers come in grade 6 (standard) or grade 4. Choose grade based on coalescing efficiencies in the chart

Stage 2

A: Activated Carbon

Grade A

Stage 2 adsorber polishes air stream of final trace amounts of hydrocarbon vapors with an efficiency of 99%+.

What is the expected life of my BA-Series filter element?

expected life of the filter elements is entirely dependent on the quality of the incoming compressed air, but can be several thousand hours. However, the elements should be changed whenever odors and/or taste become present regardless of hours in operation.

Flow Ratings

How to Order

Note: Bowl length is determined by the flow rate required. See Flow Ratings Chart above.

Note: Designate first stage; grade and media type, second stage; media type will always be “A” media, and is not designated in the part number

For Example: BAN3L-6CUG

BA-Series Replacement Elements

Note: Each repair kit contains (1) coalescing element, (2) activated carbon adsorber elements and replacement seals.

For Example: KBA3L-6CU

Mounting brackets available:

- BK-M (1/4" - 1/2" connections);

- BK-3 (3/4" - 1" connections).