Growing sometimes requires a system

The Client:

A beverage and soft drink manufacturer that is opening a new facility in the South Korea. As part of the carbonation process, their process uses a flow rate of 220 kg/hr at 20 bar pressure.

The Problem:

The beverage manufacturing facility is expanding its process beyond its current capacity. This expansion calls for larger supply need for CO2. Since they are going to be purchasing more CO2, They are concerned about the purity of the CO2 that will be coming in contact with products and the possibility of contamination. The growth in production and batch size has caused them to be concerned about the financial burden of losing product because of bad or impure CO2. Along with this concern, they have budgetary constraints for this project. The facility expansion controls a large amount of the overall budget. Coca Cola’s Recall of 30 million cans and bottles in 1999 showed how harmful CO2 contamination can be for human consumption and how the resulting recall and product loss can affect the yearly financials of the overall company. The new facility that the client is opening wants to ensure the sterility of its CO2 supply along with making sure that they have a cost efficient filtration system. They are extremely interested in getting a filtration system that has low replacement costs and long lasting filtration elements.

The Process:

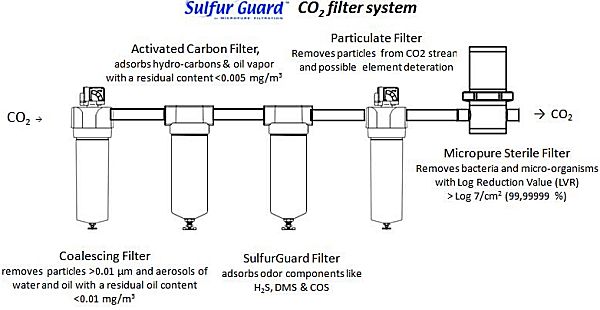

The Engineers at Micropure reviewed the specific application and needs of the client and their new facility. Micropure presented them with a proposal for its patented SulfurGuard CO2 filtration system. The flow rate and total consumption allows the engineers to offer the client a system using food grade aluminum housings as opposed to costly stainless steel.

The Solution:

In this specific application, Micropure recommended that that client install a SulfurGuard system with 19” elements and a 1 inch pipe size. This system will give the client a long replacement interval as well as low pressure drop from phase to phase. The top loading design allows for quick and simple filter element change out saving valuable production time. Since each phase is contained in a gasketed element, there is no messy carbon to deal with during the filter change out. All of these factors allowed the customer to receive the best system for their application. The client received a system with low pressure drop, high quality filtration, low replacement costs and long replacement intervals.

- For Bulk CO2 used at Soft drink, Beer and Soda

- Meets CO2 quality requirements of ISBC

- Food Grade Aluminum Housings

The patented SulfurGuard CO2 filtration system puts the process gas through several phases to ensure the post filtered CO2 is 100% sterile, free of any possible contaminants and safe for use in food and beverage applications. The first stage is an oil and liquid coalescing phase that removes particles and oil/liquid droplets. The second phase removes any aromatic hydrocarbons that are present in the CO2 stream. In the third stage, the filter will remove sulfur compounds, oxygenated aromatic hydrocarbons and aldehydes. The final stage, usually installed after the carbonators, is the sterile filter. This filter will remove all particles down to .1 micron absolute as well as any bacteria that may have been present in the CO2 stream. Having these phases present in a system ensures that the filtered CO2 is 100% safe for use.