Sterile air filters reduce batch contamination, spoilage and product loss, effective sterile air filtration is a necessary part of your process. Especially important in the food, beverage, and pharmaceutical industries, sterile air filtration protects your product from harmful submicron particle contamination and bacterial transfer or growth.

It also helps protect production yield, especially in high-tech industries (electronics, plating, magnetic media, etc.) where submicron particle contamination can significantly reduce yields, resulting in product and dollar loss. The use of high efficiency submicron air filters have become a standard “current good manufacturing practice” allowing for more productive and economical processing.

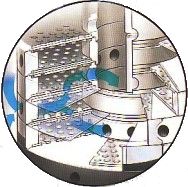

Self-sealing PTFE membranes with a 0.1 micron retention efficiency for air are sandwiched between perforated stainless steel segments within an stainless steel housing. The independently functioning modular segments are clamped together by a stainless steel tension rod that provides continued support upstream and downstream of the filter membrane. The required cartridge length and diameter are determined by your application.

Unlike conventional pleated cartridges that degrade with each sterilization, MicroPure filters can be steam sterilized in place up to 150 times with no loss of filtering effectiveness, as validated by an internationally recognized food laboratory. Other sterilization or cleaning methods commonly used are autoclave, hydrogen peroxide, steam, or a variety of sanitizing agents.*

When membrane replacement becomes necessary, the operational-and disposal-cost is considerably lower than for other filters. With MicroPure filters, only the small membrane media are replaced-not the entire cartridge.

Due to the porosity of our double-layer PTFE membrane, MicroPure filters permit higher flow rates than conventional filters, while maintaining submicron, bacterial retention efficiency.**

The rugged, reliable design of MicroPure Segmented Filters has been subjected to extensive testing in Europe and the United States, with more than 5,000 systems installed in food-and beverage-processing applications.

The results are unquestionable: MicroPure Segmented Filters, designed for two-way flow, ensureconsistent, uncompromised security for any application.

If you have a small application or a small budget the Mini Filter Series might be the solution to your filtration needs. The same great quality, segmented design and exceptional features at a lower cost to you.

If you have a small application or a small budget the Mini Filter Series might be the solution to your filtration needs. The same great quality, segmented design and exceptional features at a lower cost to you.

Head Plate

Filter Media

Segment with Inside Openings

Segment with Outside Openings

End Plate

Steam flows into the openings on the outside of each segment disc and passes through the filter and into an adjacent disc.

Steam flows into the openings on the outside of each segment disc and passes through the filter and into an adjacent disc.

*Check for chemical compatibility of PTFE prior to selecting a sanitizing agent.

**Reference laboratory report RP5268-challenge organism bacillus Stearothermophilus at a concentration of 1 x 105 spores/ml.

| Technical Data | ||

|---|---|---|

| Maximum Operating Pressure | 232 psig | 16 bar |

| Maximum Differential Pressure | 75 psid | 5.2 bar |

| Maximum Reverse Pressure | 75 psid | 5.2 bar |

| Pore Sizes | .1 micron absolute. (Other sizes available upon request) | |

| Material of Construction: | ||

|---|---|---|

| Housing | 304 SS | |

| Segmented Filter Discs | 304 SS | |

| Filter Media | 304 SS | |

| O-Rings | EPDM | |

Micropure Filtration, Inc. provides a five year limited warranty on all parts except O-rings and media. A one year warranty on filter media is based a maximum loading of 140 million particles per cubic meter (normal conditions). These warranties extend only to media purchased from Micropure or a certified Micropure Filtration Vendor.

Visit Us at

Booth 6002